PROTECTIVE CLOTHING FOR HEAT AND FLAMES

EN ISO 14116 – This standard specifies a test method for the materials allotted for use in the manufacture of protective clothing (or gloves) with electrostatic dissipation to prevent incendiary discharges.

EN ISO 14116 CERTIFICATION REQUIREMENTS

DESCRIPTION

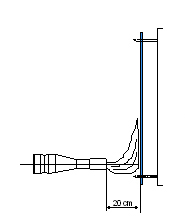

ISO 15025

Procedure A: superficial ignition, the burner is placed perpendicular to the fabric surface. Flame is applied for 10 s and the following information is observed and recorded:

- Whether the flame reaches the upper border or any border of the sample.

- Post-combustion time.

- Post-incandescence time.

- If post-incandescence spreads beyond the ignited area.

- Peeling of residues.

- Whether the residues ignite the filter paper.

- Whether a hole forms and in which layer.

Requirements for limited flame spread property 1: When testing in accordance with the ISO 15025 standard, procedure A, materials must comply with the following requirements:

- The lower part of the flame or hole may not reach the upper or vertical border of any sample.

- Ignited remains may not peel off from any sample.

- Embers from the charred part may not spread to unaffected areas after the flames cease.

Requirements for a limited flame spread property 2: When testing in accordance with the ISO 15025 standard, procedure A, materials must meet the following requirements:

- The lower part of the flame or hole may not reach the upper or vertical border of any sample.

- Ignited remains may not peel off from any sample.

- Embers from the charred part may not spread to unaffected areas after the flames cease.

- No sample may form holes.

Requirements for limited flame spread property 3: When testing in accordance with the ISO 15025 standard, procedure A, materials must comply with the following requirements:

- The lower part of the flame or hole may not reach the upper or vertical border of any sample.

- Ignited remains may not peel off from any sample.

- Embers from the charred part may not spread to unaffected areas after the flames cease.

- No sample may form holes.

- Post-combustion time for each individual sample may not be greater than 2 seconds.

ISO 13934-1

Five samples in the warp direction and 5 samples in the weft direction are tested for each material.

Test: the test sample is set in the clamps. The dynamometer is started with a constant speed of 100 mm/min, setting one of the clamps in motion (moving clip), which continues until the test sample is broken.

Tensile properties: traction resistance of exterior material or the group of clothing must be at least 150 N in both directions (warp and weft).

ISO 13937-2

Five samples are tested in the warp direction and 5 samples in the weft direction for each material.

Test: test sample is set in the clamps, with a bolt on each of them. The non-cut part of the test sample is left free. The dynamometer is started with a constant speed of 100 mm/min, setting one of the clamps in motion (moving clip) and continues to tear the fabric until the 2.5 cm mark from the border of the test sample.

Calculation of the tear: the resulting graph from each of the samples tested is divided into 4 equal parts. The first part is discarded and the two highest and lowest peaks are chosen from the three remaining parts. A mean is taken from the 12 values obtained from each test sample.

Tear resistance: tear resistance of exterior material or the group of clothing must be at least 7.5 N in both directions.