What kind of risk does the work area imply ?

Today, at Marina Textil we have textile solutions for protecting against following hazards : Molten metal splashes , Small spatter in welding and related techniques, chemicals spreads, Cement-ferrous projections, Flashfire , Structural fire , Bush Fire, Electric arc flash, Combustible dust ,Flammable Gases , Atex zones, Monochromatic spaces with road traffic, Deflagrations, Electrostatic charges…

[social_buttons facebook=”true” twitter=”true” google_plus=”true” linkedin=”true”]

It is very convenient to know the risks that can occur in each workplace. A good study of the workplace and advice from professionals in the sector can provide very good information in this regard. Companies in the sector such as audits of occupational hazards, would be the most suitable to carry out this type of studies.

What type of regulations or standards are in each case

All risk implies an European, International, Chinese, American, Russian regulations, norms, standards where the FR( Flame retardant) / AR (Arc rated) garments and fabrics are tested and certified.

Some of them:

EN11612 ( https://youtu.be/Hmcyp4arddE ) tests the behaviour of protective fabrics and garments against fire, flames and heat; NFP70E / ASTM F1959 tests the behaviour of protective fabrics and garments against an Electric Arc in open space “Open Arc”, etc.

All personal protective FR / AR clothing, as well as the components that compose it (as well as fabric, zippers, retro-reflective bands, etc.) must comply with the regulations required for each case and be certified in official laboratories where they issue, control, test and attest that the regulations are complied with.

In the Category III of Protective Clothing , the laboratories control that the process, fabric, garments, etc. always follow the original pattern from the beginning of the certification for a validity of 5 years, giving a better guarantee and coverage to the end user so that the specified materials are always remain the same during the manufacturing and supply chain.

A good Audit report will also imply a good recommendation of the Regulations to be complied with for the Protective Clothing to be used in the workplace. However, and every day and more, there is a growing need on the part of the end user for advice on our part in this regard.

In what season will they be used ?

Depending on the climatic conditions of the type of work, it is convenient to have some guidelines such as the following:

Winter:

For the winter season, it is recommended, apart from complying with the protection FR /AR regulations, that the solutions can protect from the cold temperatures ( if exists).

Thus, most solutions are multi-layer FR / AR solutions: winter jacket and trousers with a padding , light sweater / jacket or shirt, with a knitted underwear.

All the layers must be protected against the flame (FR) and if they must comply with the electric arc regulations (Box Test, or Open Arc) they must be suitably marked in the informative note (if they have been tested jointly or separately).

For the summer season:

Prioritize lightweight, breathable garments that help the wearer stay cool and comfortable.

For the halftime seasons (spring and autumn):

Use fireproof fabrics and garments that can protect against climatic agents such as wind or rain. Said protective garments against rain, cold, flame must be suitably produced by multi-standard waterproof FR /AR fabric and heat-sealing properties will be needed once you certify EN343.

Nowadays and more and more, Softshell garments are winning more prominence when we talk about protection against strong wind. (ie maintenance in wind farms due to their work at height). Do not trust yourself, and let yourself be advised by a good manufacturer of workwear as well as by a good manufacturer of the raw material ( protective AR / FR fabrics ); technical fabrics such as those from Marina Textil where multilayer fabrics give full guarantee of compliance with fire regulations, FR flame, electric arc (AR) and giving very good coverage against high speed winds.

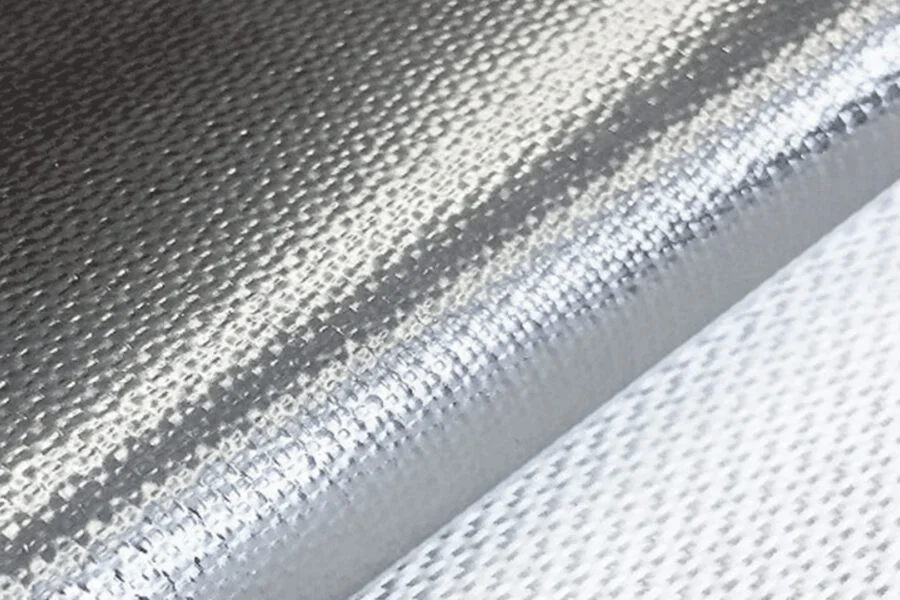

What type of FR / AR fabrics should we use?

Currently there are non-permanent fabrics (chemical treatment) of very low cost but also of very little durability. And the inherent flame retardant fabrics due to their molecular composition of fibres. DNA is permanent protection and its durability is longer. Always in case of any doubt, Marina Textil will be at your disposal to guarantee you the best proposal both in knitted fabrics, as well as woven , Softshells, as well as in multilayer fabrics with a membrane for making the garments mentioned in the previous point number 3.

What are the best fibres to guarantee inherent, permanent protection?

The fibres where you will not need to worry about their inherence are the following: Meta Para Aramides, Viscose FR, Modacrylic or Polyacrylic FR, Oxidized PAN, Vynal, Carbon, Polyamides High tenacity, Trevira , amongst the main ones. Many of them are used in our daily productions in our manufacturing plant in Barcelona of our FR /AR Marina Textil fabrics. Fiber like acetate, cotton , poliesters, poliamides low tenacity,polypropylene, wool, acrylic, lyocell, silk , elastane are not flame retardant.